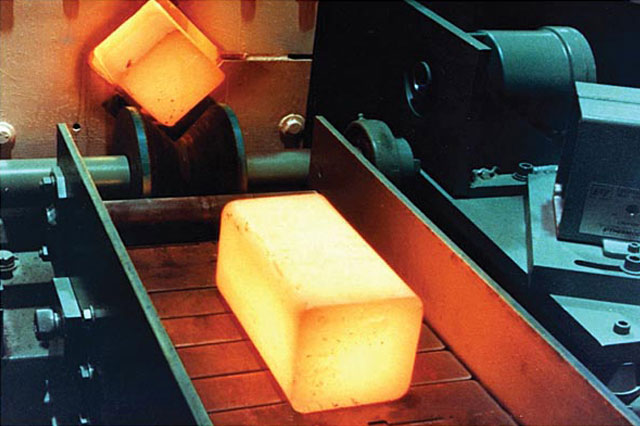

We have established ALUMINIUM ALLOY INGOTS manufacturing unit known as PEARL METAL CAST Plot No. 5, Sector-6, Faridabad. Our product range includes all grades of aluminium alloys and aluminium base master alloys (ADC / LM Series) having ingots manufacturing capacity of 2000 MT per month under the flagship of our parent company Steel Forge Faridabad with the same knowledgeable management.

This unit is equipped with Skelner Tilting type furnaces, 2 Nos. with a lot capacity of 8 M.T. each with temperature recorder and the furnaces are gas / oil fired.

Other than this our mission to achieve customer satisfaction, we always keeps quality parameters at our top most priorities. Our quality assurance department is well equipped with laboratory for chemical testing & has advanced analyzing equipment.(List as below):

| Sr.No. |

Name of the Equipment |

Make |

Qty/No. |

| 01 |

Spectro Analyzer |

SpectoMaxx (Germany) |

One |

| 02 |

Spectro Analyzer (Mobile Portable) |

SpectoMaxx (Germany) |

One |

| 03 |

Brinnel Hardness Tester (3000 Kg.) |

Krystal (Canon) |

One |

| 04 |

Meta Scope (Portable) |

Sobhetronics |

One |

| 05 |

Table Type Spectroscope |

Sobhetronics |

One |

| 06 |

Tensile Testing Machine |

F.I.E. |

One |

| 07 |

Polishing and Buffing Machine |

Sumitra |

One |

| 08 |

Impact Testing Machine |

F.I.E. |

One |

| 09 |

Optical Pyrometer |

Toshniwal |

One |

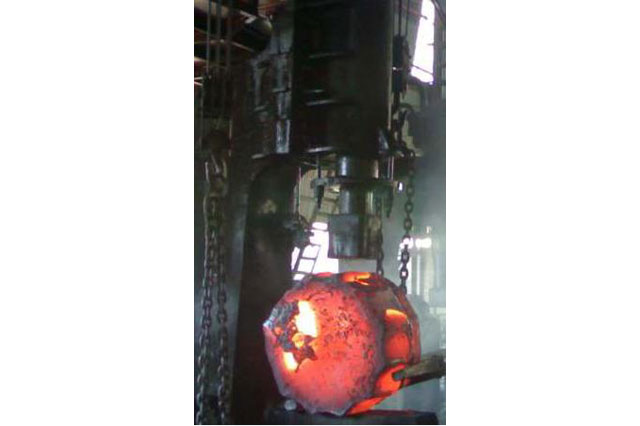

J.A.V. Forgings Pvt. Ltd. has all the necessary facilities available within the works premises to manufacture the aforesaid items including heat-treatment, physical/chemical & non-destructive testing (U.T., M.T., & D.P.T.) and machining/drilling/serrations etc. All the international third party inspection agencies like M/s. LRIL, BVIL, DNVGL, TUV, BAX Counsel, JACOBS, EIL/CEIL, PDIL, NPCIL, IRS, UIL, TPL, TOYO are regular visitor of company Forgings Pvt. Ltd. for their stage inspection to ensure supplies well within contractual delivery periods. The complete manufacturing procedure of company has been approved and accepted by these agencies. All the testing equipments and measuring instruments used in company Forgings Pvt. Ltd. are periodically calibrated by CANON and National physical Laboratory. Besides, company has a team of highly experienced technical staff right from the General Manager to the Supervisor Level in all the departments including Quality Control which is headed by a highly qualified and experienced personnel assisted by well qualified and experienced Q.C. Engineers with ASNT LEVEL-2 certified for Visual, Ultrasonic, Magnetic Particle and Liquid Penetrate Non Destructive tests and are working under fruitful guidance of the Managing Director and Chairman, Mr. I. C. Singhal who has vast forging experience of 29 years and has been involved in manufacturing forging items which were otherwise being imported or procured from distant places by industries of northern states.

MACHINING

Customers prefer to place order on J.A.V. due to wide range machining facilities available within its premises. J.A.V. is fully equipped with all types of machines to conform to any machining drawing, tolerance and accuracy requirements of the customers. Latest machines are installed for accurate and fast machining. One of them is CNC Machine of M/s LMW (mode X-880-LAL-2) installed at our sister concern M/s Steel Forge, Faridabad which has eight computerised operations simultaneously in one setting with zero. This machine is most suitable to supply large quantities of accurately machined an ground items of Automobile Industries, Railways, Defence and power plants, Besides number of Lathe, drilling, milling and shaper machines are installed to meet production of both open and closed die forging plants, without any backlog. Complete range of tools and dies required for manufacture of closed- die forged items are prepare in J.A.V./STEEL FORGE machine shops itself. All the machines are suitably covered with overhead electric cranes of 5/10 MT capacity.

PROVISION OF RESOURCES (INFRASTRUCTURE)

List of Machines - Forge Shop

| Sr No |

Machine Name |

Size/Capacity |

Qty |

| 01 |

Forging Furnace |

14 x 8 x 7 ft |

2 Nos |

| 02 |

Steam Hammer |

5 M.T |

3 Nos |

| 03 |

Boiler (Lancashire) |

160 PSI |

1 No |

| 04 |

Overhead electric crane |

10 MT |

1 No |

| 05 |

Overhead electric crane |

5 MT |

1 No |

List of Facilities – Heat treatment Shop

| Sr No |

Machine Name |

Size/Capacity |

Qty |

| 01 |

Automatic temp. controlled Oil fired bogie type Heat- treatment furnace with Temp recorder, Temp controller & Temp indicator |

5.5 x 4.5 ft |

1 No |

| 02 |

Heat- treatment furnace with Temp recorder |

5 x 2.5 x 1.5 ft |

1 No |

| 03 |

Oil quenching tank |

6 x 10 ft depth |

1 No |

| 04 |

Water quenching tank |

8 x 12 x 12 ft depth |

1 No |

| 05 |

Overhead electric crane |

5 MT |

1 No |

| 06 |

Overhead electric crane |

10 MT |

1 No |

| 07 |

Muffle Furnace (Electric) |

4 x 4 x 12 Inch |

1 No |

| 08 |

Muffle Furnace (Electric) |

9 x 9 x 12 Inch |

1 No |

List of facilities - Cutting Shop

| Sr No |

Machine Name |

Size/Capacity |

Qty |

| 01 |

Bend Shaw |

1000 MM |

1 No |

| 02 |

Bend Shaw |

450 MM |

2 Nos |

| 03 |

Bend Shaw |

250 MM |

1 No |

| 04 |

Overhead electric crane |

20 MT |

1 No |

| 05 |

Overhead electric crane |

10 MT |

1 No |

| 06 |

Overhead electric crane |

5 MT |

2 Nos |

| 07 |

Hacksaw machine (Power) |

450 MM |

1 No |

List of facilities - Test & Inspection

| Sr No |

Machine Name |

Size/Capacity |

Qty |

| 01 |

Chemical test Lab (Fully equipped) |

- |

1 No |

| 02 |

Oven |

14x14x14 inch |

1 No |

| 03 |

Muffle Furnace (Electric) |

4 x 4 x 12 Inch |

1 No |

| 04 |

Muffle Furnace (Electric) |

9 x 9 x 12 Inch |

1 No |

| 05 |

Universal testing machine (FIE) |

20 Ton |

1 No |

| 06 |

Brinell hardness tester |

3000 Kgs x 10 mm Ball |

1 No |

| 07 |

Dynamic Hardness Tester (Digital)DHT-6 |

30-680 (HB) |

1 No |

| 08 |

Impact Testing Machine |

300 Joules |

1 No |

| 09 |

Cryocan |

11 Ltr |

1 No |

| 10 |

Cryocan |

3 Ltr |

1 No |

| 11 |

Profile Projector |

50 X |

1 No |

| 12 |

Poldi Hardness tester |

-- |

1 No |

| 13 |

Ultrasonic flaw detector(Vibronix Model 301 M) |

0 TO 5 Mtr |

1 No |

| 14 |

Ultrasonic flaw detector(ECC Make ESM-2) |

0 TO 5 Mtr |

1 No |

| 15 |

Ultrasonic flaw detector(Parikh Ind. Make PX-01) |

0 TO 5 Mtr |

1 No |

| 16 |

Magnetic crack detector (MPT) Bad Type |

3000 AMP |

1 No |

| 17 |

Magnetic crack detector (MPT) Yoke |

|

1 No |

| 18 |

Die penetrant testing facility Arocell Can |

330 ML/ 240 g |

As Req |

| 19 |

Microscope |

50X to 1000 X |

1 No |

| 20 |

Polishing machine |

- |

1 No |

| 21 |

Optical Pyrometers (Toshniwal) |

700 ºC – 1600 ºC |

1 No |

| 22 |

Intergranular corrosion test Facilities |

- |

1 No |

List of Machine/Equipment/facilities - Machine Shop

| Sr No |

Machine Name |

Size/Capacity |

Qty |

| 01 |

Extra Heavy duty Lathe |

16-36 inch |

2 Nos |

| 02 |

Heavy duty Lathe |

16-20 inch |

1 No |

| 03 |

Extra Heavy duty Lathe (Short Bed) |

6-36 inch |

1 No |

| 04 |

Heavy duty Lathe |

8-28 inch |

1 No |

| 05 |

Heavy duty Lathe |

6-16 inch |

1 No |

| 06 |

Lathe |

6-14 inch |

1 No |

| 07 |

Heavy duty Lathe |

12-20 inch |

1 No |

| 08 |

Lathe |

8-14 inch |

1 No |

| 09 |

Heavy duty Lathe (Gear Head) |

10-20 inch |

1 No |

| 10 |

Planer |

12 inch Bed |

1 No |

| 11 |

Shaper |

20 inch stroke |

1 No |

| 12 |

Radial drilling Machine |

Upto 2 inch dia Hole |

4 Nos |

| 13 |

Radial drilling Machine |

Upto 1.5 inch dia Hole |

2 Nos |

| 14 |

Pistol Grinder |

- |

1 No |

| 15 |

Bench Vice |

- |

1 No |

| 16 |

Surface Grinder |

- |

1 No |

| 17 |

Buff Grinder |

- |

3 Nos |

| 18 |

Flexible Grinder |

- |

1 No |

| 19 |

Overhead electric crane |

5 MT |

1 No |

List of Instruments - Final Inspection Shop

| Sr No |

Machine Name |

Size/Capacity |

Qty |

| 01 |

Vernier Calipers |

6 to 48 inch |

10 Nos |

| 02 |

Micrometers |

0 – 25 MM |

2 Nos |

| 03 |

Micrometers |

0 – 50 MM |

1 No |

| 04 |

Angle Protectors |

0 – 180 deg |

1 No |

| 05 |

Thread gauges |

0.5 X 4 inch |

1 No |

| 06 |

Radius gauges |

1 to 7 MM |

1 No |

| 07 |

Radius gauges |

7.5 to 15 MM |

1 No |

| 08 |

Radius gauges |

15.5 to 25 MM |

1 No |

| 09 |

Surface Comparator |

0 – 500 RMS |

1 No |

| 10 |

Measuring tapes |

3 Mtr |

3 Nos |

| 11 |

Surface Roughness Comparator |

|

1 No |

Facilities - Others

| Sr No |

Machine Name |

Size/Capacity |

Qty |

| 01 |

Generator (Kirloskar Cummins) |

180 KVA |

1 No |

| 02 |

Generator (Kirloskar Cummins) |

82.5 KVA |

1 No |

| 03 |

Hand Grinders |

- |

3 Nos |

| 04 |

Power Grinders |

- |

1 No |

| 05 |

Pistol Drill Machine |

- |

1 No |

| 06 |

Welding sets |

- |

2 Nos |

| 07 |

Gas cutting sets |

- |

2 Nos |

| 08 |

Chain Blocks |

1.0 MT – 10.0 MT |

5 Nos |